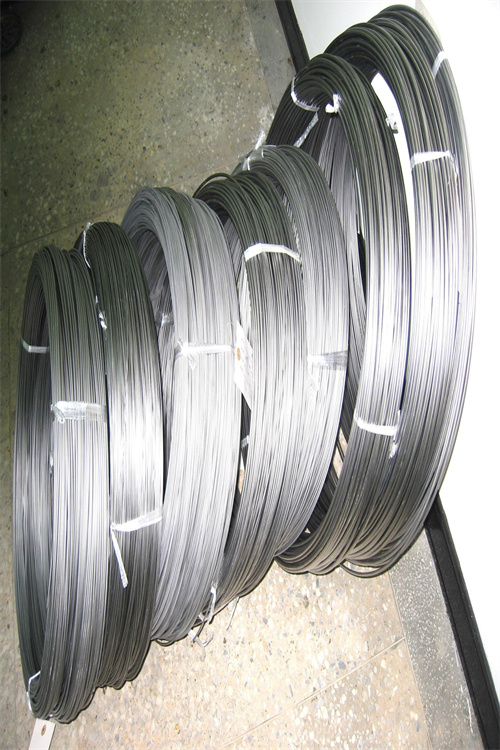

Black Anneal Wire binding wire for cloth hanger clip

Brand : Sincere

Product origin : Tianjin, China

Delivery time : 20days-25days

Supply capacity : 50000tons per month

The hot metal billet is rolled into 6.5mm thick steel bars, that is, the wire rod, and then put it into the wire drawing device to draw into lines of different diameters, and gradually reduce the aperture of the wire drawing disk, cooling, annealing, coating and other processing technology into a variety of different specifications of wire. It contains iron, cobalt, nickel, copper, carbon, zinc, and other elements. At present, annealed wire and steel wire production generally adopts drawing process and galvanizing treatment.

The main silk size is 5#-38#(silk by 0.17-4.5mm)

Characteristics: softer than ordinary black wire, more flexible, even softness, consistent color.

Application: mainly used in construction, mining, chemical industry, welding net, welding clothes rack, reprocessing, etc. After annealing, the wire becomes soft and flexibility increases, so the effect of building binding wire and reinforcing bar is more effective.

At present, annealed wire and steel wire production generally adopts drawing process and galvanizing treatment. In 1976, guangzhou galvanized iron and wire works in the first domestic application of electrolytic pickling, high pressure washing, stuck electric drying new technology test success of wire drawing line continuous production, so that the wire drawing process from intermittent production into continuous production, reduce labor intensity, reduce metal consumption. At that time, the domestic iron wire factory has been able to produce steel wire rope, spoke steel wire, umbrella bone steel wire, spring steel wire, bicycle saddle spring steel wire and other products. In the 1980s, hot plated low carbon steel wire, fan mesh wire, carbon structure wire, bed surface wire, etc.

Packing: the packing of black iron wire is the same as the packing of galvanized wire, it is divided into two parts: inside plastic and outside hemp, inside plastic and outside weaving, and first use a thin layer of plastic to wind the wire around, and then use hemp bag or woven bag to wind it!